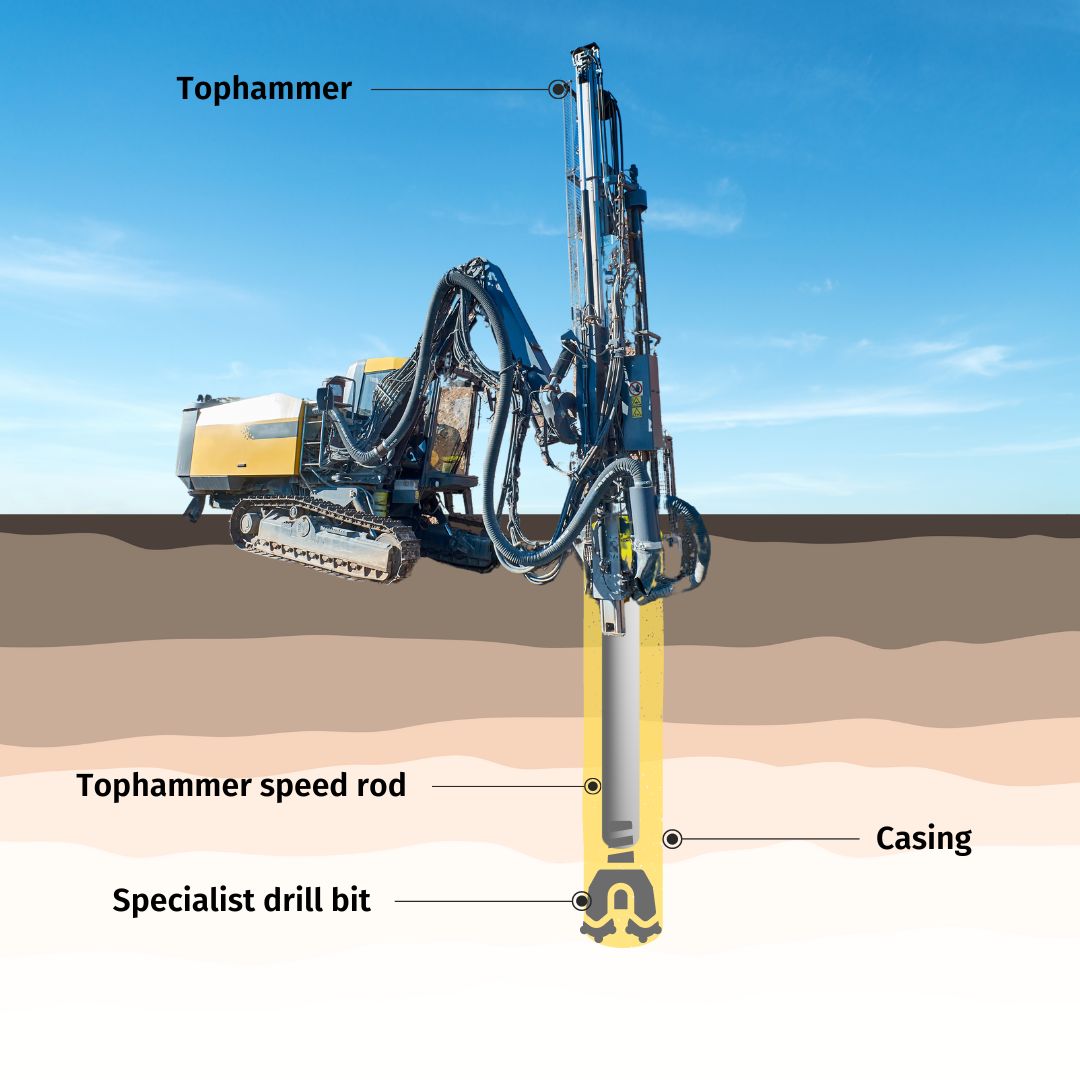

Earthing Solutions has earned a reputation for tackling earthing projects efficiently and cost effectively. We have a range of equipment and methodology for tackling even the most difficult projects. For example, we employ our tophammer case drilling system to drill through cobble and overburden to efficiently place electrodes.

How it works

Our 80mm diameter tophammer case drilling system uses standard tophammer speed rods in conjunction with 80mm casing and a specialist drilling bit that can be removed when the required depth is reached. Once the bit is removed the electrode is placed in the casing and then the casing is retracted leaving the electrode in position.

Our 80mm diameter tophammer case drilling system uses standard tophammer speed rods in conjunction with 80mm casing and a specialist drilling bit that can be removed when the required depth is reached. Once the bit is removed the electrode is placed in the casing and then the casing is retracted leaving the electrode in position.

We have been using this system for about a decade, successfully drilling to depths of 27.5m in cobble and to multiple depths in railway ballast. Another advantage of this system is it can be used in quite tight access areas.

Recommending the right system

Earthing Solutions has been providing earthing and lightning protection services since 2003, and we are continually increasing our capability. With more than 20 years’ industry experience, we know the right system to use to fit the conditions and the task.