What is soil resistivity and why is it important?

Earthing Solutions offers soil resistivity testing as part of its earthing system design service. So what is soil resistivity and why is it important?

Soil resistivity is a measure of how much the soil resists or conducts electrical current. The design of an earthing system for an electrical substation, or the design of a lightning protection system, is directly affected by the resistivity of the soil. For the most cost effective solution, you would endeavour to locate the earthing system in the area of lowest soil resistivity.

Which soils have the lowest resistivity?

Soils comprised of shale, loam or ashes tend to have the lowest soil resistivity. Soil comprised of sand, stone and gravel have the highest. Temperature, moisture content and salt content can also affect soil resistivity. A small variation in the salt content of the soil can have a major impact on soil resistivity.

How do you test for soil resistivity?

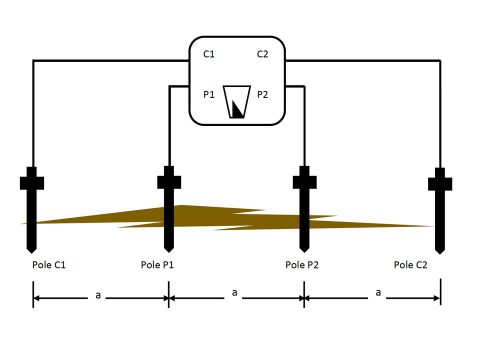

The Wenner 4-pole method is regarded as one of the most reliable methods for testing soil resistivity at greater depths and so it is one of the best soil resistivity tests for earthing system design.

The method works by emitting an electrical signal into the ground via probes and measuring the returning signal. To apply the Wenner 4-pole method, you need an instrument with four electrode probes; two probes for current injection and two for potential measurement. The probes only penetrate a few inches, but the signal penetrates several metres.

Earthing Solutions uses the Megger DET4TD, a hardwearing and reliable testing unit. The Megger testing unit is designed to be self-checking to allow the operator to focus on collating and understanding the results.

The four electrode probes are placed into the ground equal distances apart. The two outer electrodes inject current into the soil and the two inner ones, known as the potential electrodes, measure voltage which is used to calculate the soil resistance.

Earthing Solutions uses the Megger DET4TD, a hardwearing and reliable testing unit. The Megger testing unit is designed to be self-checking to allow the operator to focus on collating and understanding the results.

The four electrode probes are placed into the ground equal distances apart. The two outer electrodes inject current into the soil and the two inner ones, known as the potential electrodes, measure voltage which is used to calculate the soil resistance.